High temperature resistance anti-corrosion coating

- Home

- Products

- Inorganic ceramic coating

- High temperature resistance anti-corrosion coating

High temperature resistance anti-corrosion coating

Description

Feature

- Burning resistance and heat-resistant

- High hardness

- Low curing temperature

- Weatherability

- Colorful

Specification

| Item | EST-S(0~X) | ESTKS(0~X) | EST-W(0~X) | Teat method | note |

| Solid content(%) | 48±2 | 48±2 | 48±2 | 150 ℃ 30 mins | adjustable |

| viscosity(cp) | 10~100 | 10~100 | 10~100 | A&D SV-10 | adjustable |

| Specific gravity | 1.1~1.3 | 1.1~1.3 | 1.1~1.3 | hydrometer | |

| appearance | orange | balck | white |

Process condition

| Item | EST |

| Substrate pre-treatment | 1.Sand blasting pre-treatment 2.hair-line surface pre-treatment 3.Acid-Alkai pre-treatment |

| Solution mixing | NA |

| Solution temperature (°C) | RT |

| Substrate temperature (°C) | RT~60 |

| Coating | Spray/Dip |

| Curing temperature (°C) | 80°C 5 mins → 200 °C 30 mins |

Performance

| Item | EST | Test method | Reference |

| Adhesion | 5B | 3M scotch 600Tape | ASTM3359 |

| Contact angle | >80° | Goniometer | |

| Pencil hardness | 7H~8H (@25°C) 7H~8H (@300°C) |

1kg | ASTM3363 |

| Solvent resistance | MEK | Wipe 200 time | |

| Chemical resistance | 0 |

48 hours | |

| Salt mist resistant | No peeling, No damage | 5% NaCI x 3000 hours | |

| Heat resistance | > 800°C | ||

| Weather resistance | Gloss difference <10% | Weather-O-meterx 5000 hours | |

| Abrasion test | No scratch | 1.5 kg 500 times (3M scrub sponge) | |

| Acid resistance | No peeling, No damage | 10% Aqua Regia 20 hours | |

| Acid resistance | No peeling, No damage | 10% H2SO4 30 hours | |

| Acid resistance | No peeling, No damage | 10%HNO3 30 hours | |

| Acid resistance | No peeling, No damage | 10% (HNO3+H2SO4) 30 hours | |

| Alkali resistance | No peeling, No damage | 5%NaOH 10 hours | |

| Alkali resistance | No peeling, No damage | 10% NH3 30 hours |

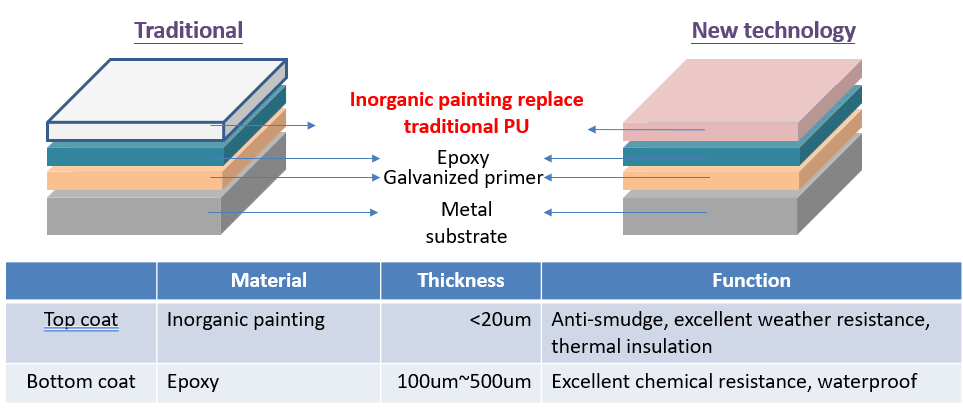

Product structure in Severe Corrosion environment

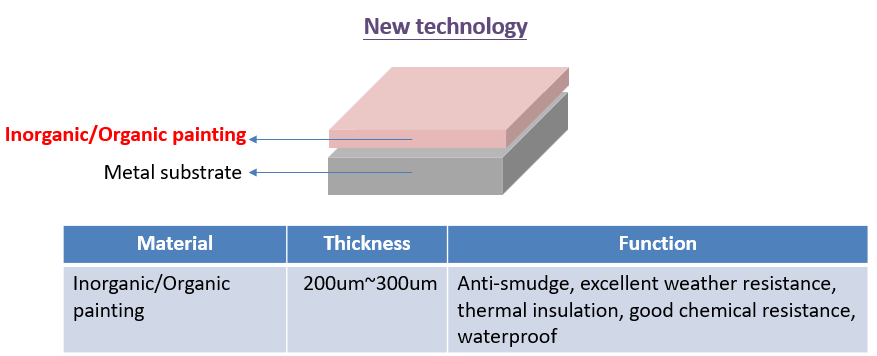

Normal Corrosion environment

Application