Photocatalyst coating foaming ceramics

- Home

- Products

- Photocatalyst coating

- Photocatalyst coating foaming ceramics

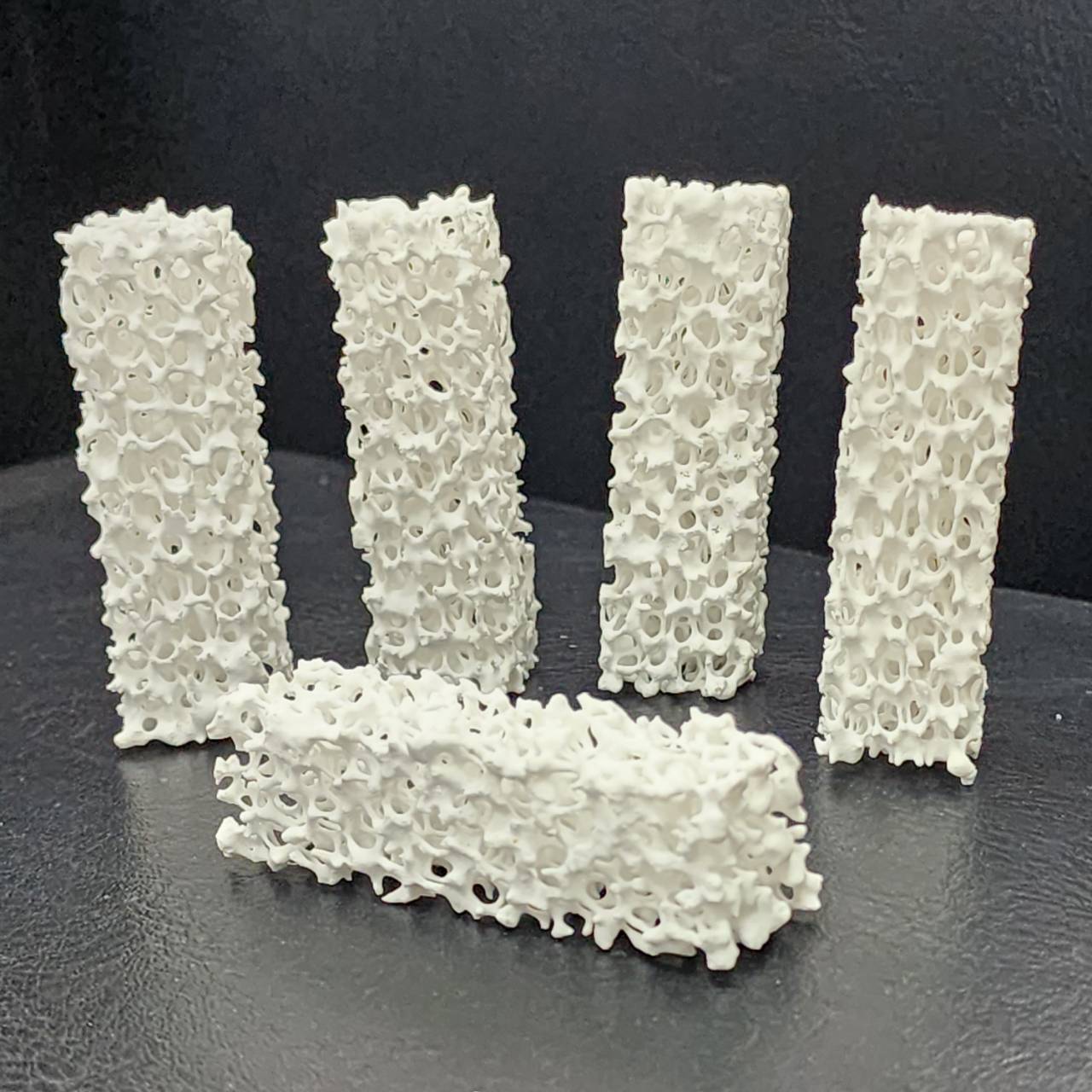

Photocatalyst coating foaming ceramics

Description

Traditional photocatalyst coating with organic binder should be short life time, because photocatalyst decompose organic binder. GiantNano photocatalyst coating with inorganic binder on foaming ceramics is stable under UV light exposure, even UVC and UVB light.

GiantNano Photocatalyst coating foaming ceramics can decompose total volatile organic compound and harmful gases, such as formaldehyde, methanol, NOx, bacteria, virus….

Feature

- High decomposition rate

- long lasting

- easy to clean

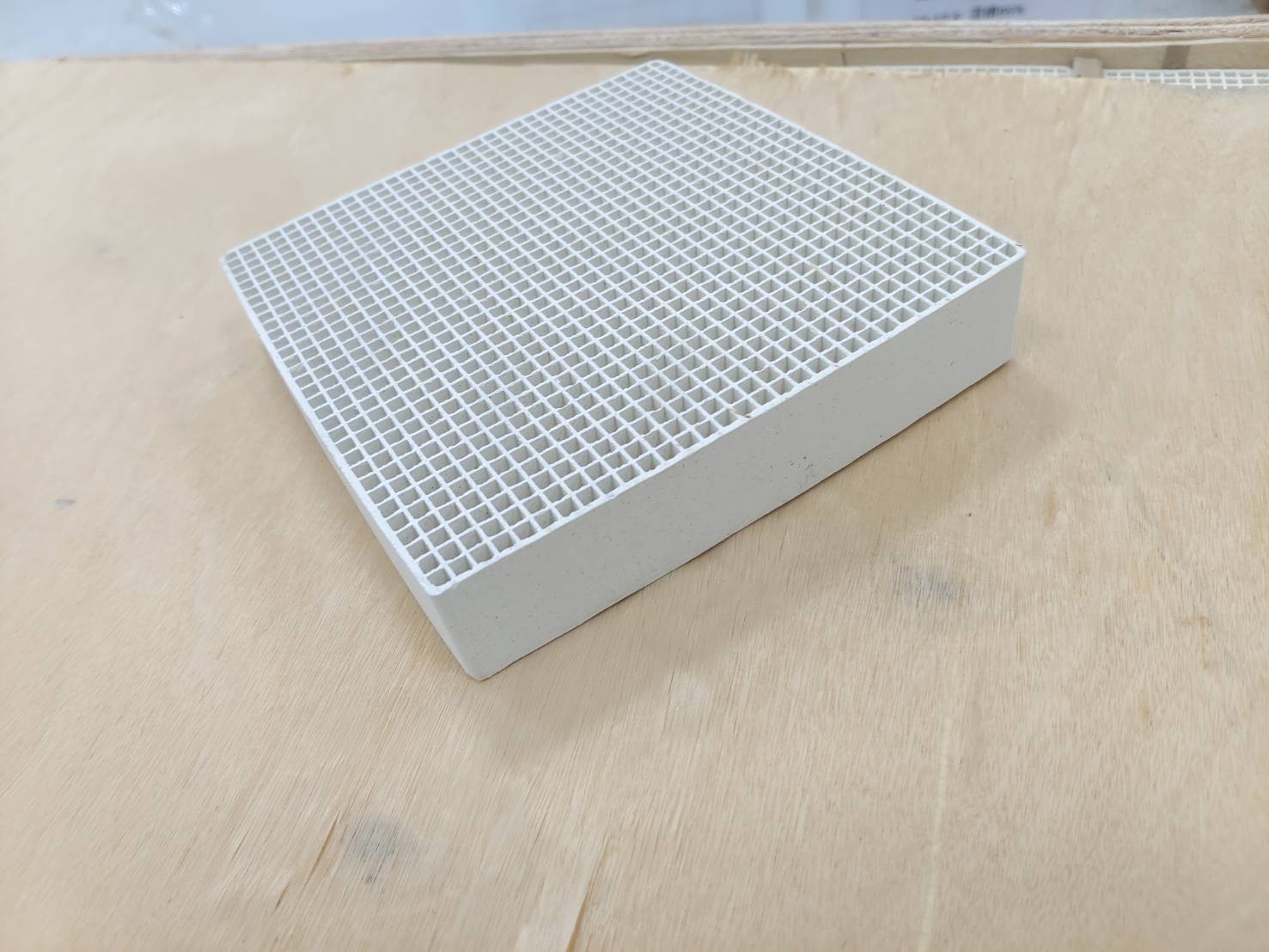

- Porosity of foaming can be customized

Specification

| Item | Result |

| Appearance | Light yellow |

| Porosity of foaming(PPI) | 10~30 |

| Density (g/cm2) | 0.9~1.5 |

| Thickness of foaming ceramics (mm) | 3~10 |

| Thickness of photocatalyst coating (um) | 20~100 |

Process condition

| Item | PSG | Mark |

| Solution temperature(°C) | 23~27 | |

| Coating method | Spray/Roller | Dry film thickness >100nm Higher dry film thickness, higher UV-cut percentage |

| Coating environment-temperature (°C) | 23~27 | |

| Coating environment-humidity (%) | 50~80 | |

| Curing temperature (°C) | 300~600 °C 30min |

Performance

| Item | PSB-OX | PSG-PX | PSG-HX | Test method | reference |

| Adhesion | 5B (Under 5 days sunlig ht) | 5B | 5B | 3M scotch 600 tape | ASTM3359 |

| water contact angle | <20° | <10° | <20° | Goniometer | |

| Pencil hardness | 5H (Under 5 days sunlight) | 7H | >8H | 1kg | ASTM3363 |

| Gloss 60° | >170 | >170 | >170 | Gloss meter | |

| Sterilization | >80% | >80% | >80% | FIRDI(visible light) | TN-002 |

| Sterilization | >99.99% | >99.99% | >99.99% | NCKU (UV light) | TN-002 |

Reliability Test Summary

| Test item | Test condition | Test result | Standard condition | Standard reference |

| Damp heat | 2000 hours | △T<0.1% | 1000 hours | IEC 61215 |

| Thermal cycling | 400 cycles | △T<0.6% | 200 cycles | IEC 61215 |

| Humidity freeze | 20 cycles | △T<0.3% | 10 cycles | IEC 61215 |

| UV | 60 kWh | △T<0.3% | 15 kWh | IEC 61215 |

| Salt mist | 96 hours | △T<0.6% | 96 hours | IEC 61701 |

| Acid Resistance | 1M HCl | △T<0.3% | 1M HCl |

Application